Highest Precision with Laser Micromachining

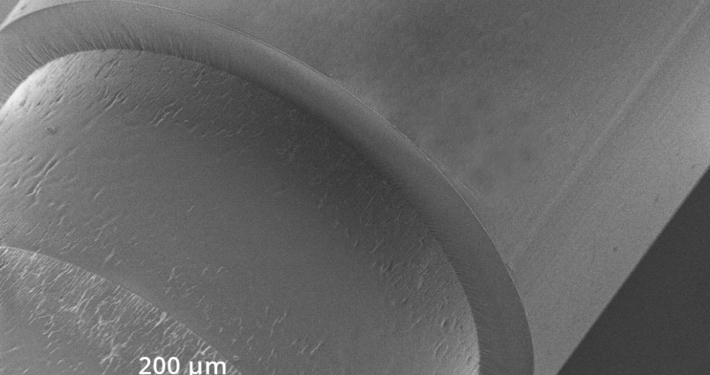

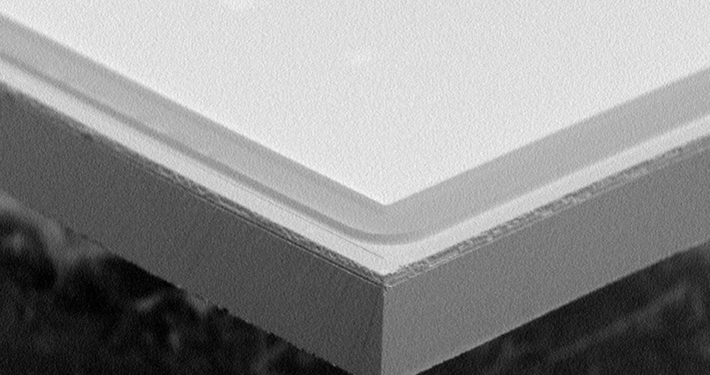

The field of electronics, semiconductor processing, and medical instrument manufacturing is witnessing a trend of progressive miniaturization. This trend is characterized by the production of increasingly smaller structures, while at the same time, there is a growing demand for the highest level of precision in terms of surface quality, absence of burr, and materials residues. Traditional fabrication technologies are increasingly facing limitations in meeting these demands; however, laser micromachining provides optimal conditions for achieving the required quality and precision. This is because laser micromachining is a contactless process, and the extent of the heat-affected zone is very small.

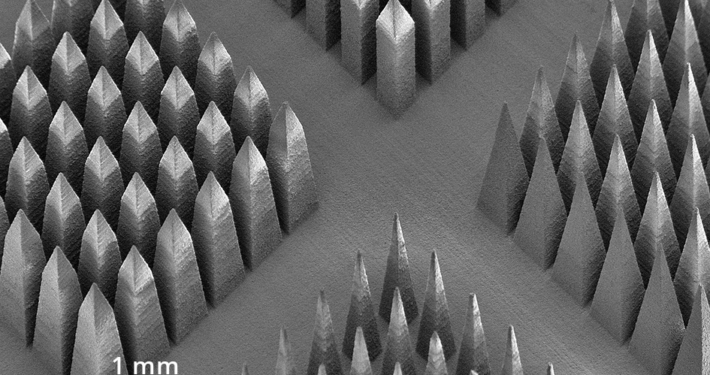

Classical areas of applications for laser micromachining lie within the ambit of the laser micro drilling, laser fine cutting, laser micro structuring and the laser micro engraving. Moreover, innovative laser separation processes such as TLS-Dicing or laser ablation processes for the manufacturing of cylindrical holes, undercut geometries or molds are finding their way into the industrial production.

3D-Micromac has introduced laser-based sample preparation, which opens up new possibilities for laser micromachining. This technology offers patented workflows for TEM analysis, X-ray microscopy, atom probe tomography, and micromechanical testing, complementing existing methods of sample preparation, such as focused ion beam (FIB) micromachining. Laser-based sample preparation provides up to 10,000 times higher ablation rates, resulting in significantly lower cost of ownership (CoO) when compared to FIB.

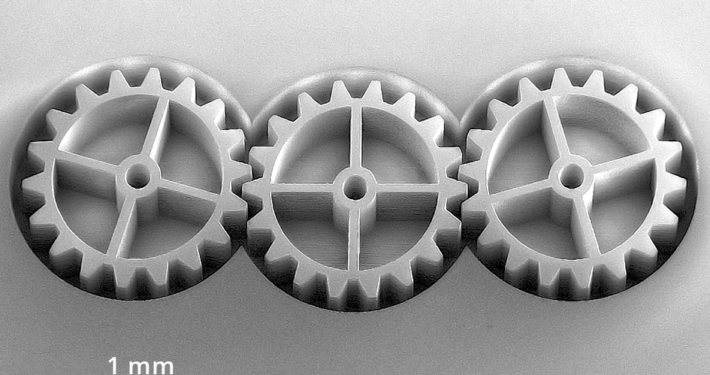

In additive manufacturing, Micro Laser Sintering combines the advantages of 3D printing and micro machining for the first time. Micro metal parts of incredible accuracy, detail resolution and surface quality are manufactured this way.

Contact

Please contact our technical sales team for more information.

Frank Richter

Tel: +49 371 40043-222

sales@3d-micromac.com

Advantages of Laser Micro Machining

- Easy capability of being automated

- Straightforward process monitoring

- Forceless and contactless machining

- Minor heat-affected zone

- Marginal modifications to the microstructure

- Machining free of burr and bulging

- High flexibility regarding design of tiny structures

- High machining speed

- High precision

- Constant machining quality

- No additional tooling costs by wear

In order to use the advantages of the laser processing optimal, efficient and forward-looking processes with greatest production efficiency are the key to the success. That’s why we offer our customers qualitatively, high end, reliable and customer friendly machines for all applications of the laser micromachining to help increase the production efficiency of our customers to optimize procedures and reduce costs.