Micromachining Excellence

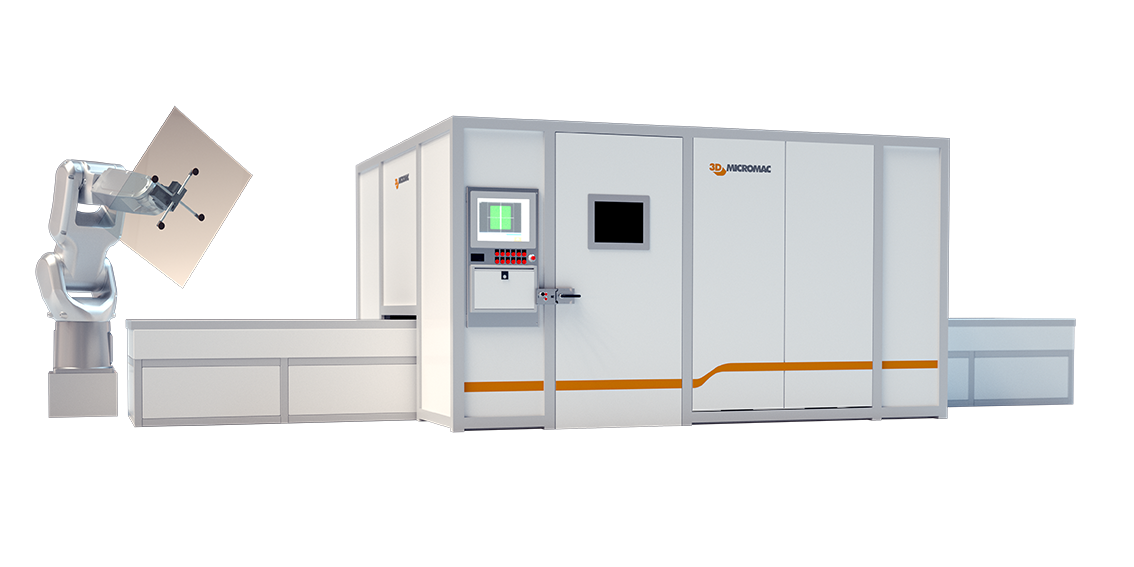

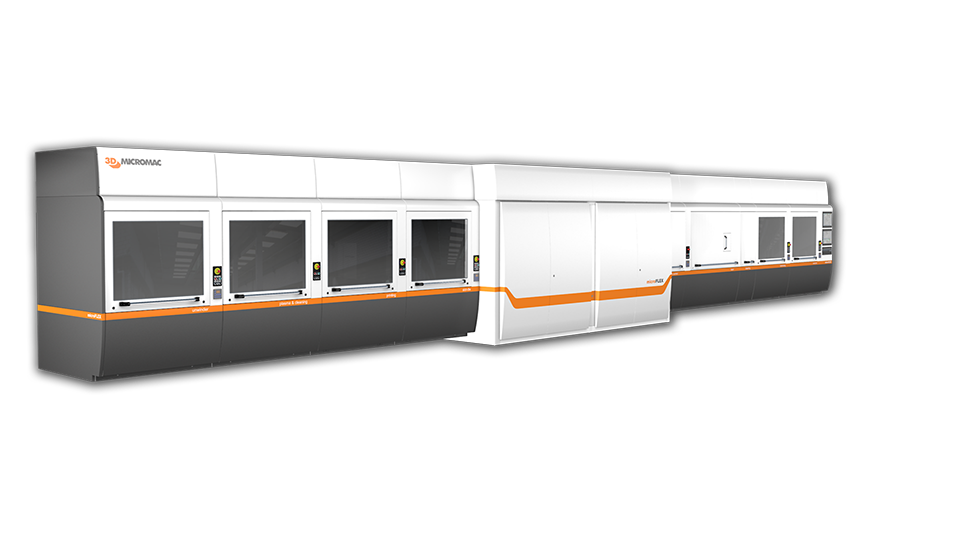

3D-Micromac AG is the industry leader in laser micromachining. We develop processes, machines and turnkey solutions at the highest technical and technological level. Our aim is to provide superb customer satisfaction even for the most complex projects.

3D-Micromac delivers powerful, user-friendly and leading edge processes with superior production efficiency. These proprietary technology innovations are now readily available on a worldwide scale.

Configurate your Laser System here!

News

Social Media

Do you need to increase your productivity and efficiency? 📈 #Lasertechnology might be the right solution for you. We develop processes & #lasersystems at the highest technological level, and setting worldwide standards in #lasermicromachining. We are ready for your task 💪

🌟 We have a reading recommendation for all those interested in MicroLED technology. 💡 In this new article from #PhotonicsSpectra, our CEO, Uwe Wagner, shares his expertise and #insights on 3D-Micromac's way of #manufacturing #MicroLEDs. 🔎 Read here https://ow.ly/mErw50QJaC4

3D-Micromac

3D-Micromac 3D-Micromac AG

3D-Micromac AG