Micromachining Excellence

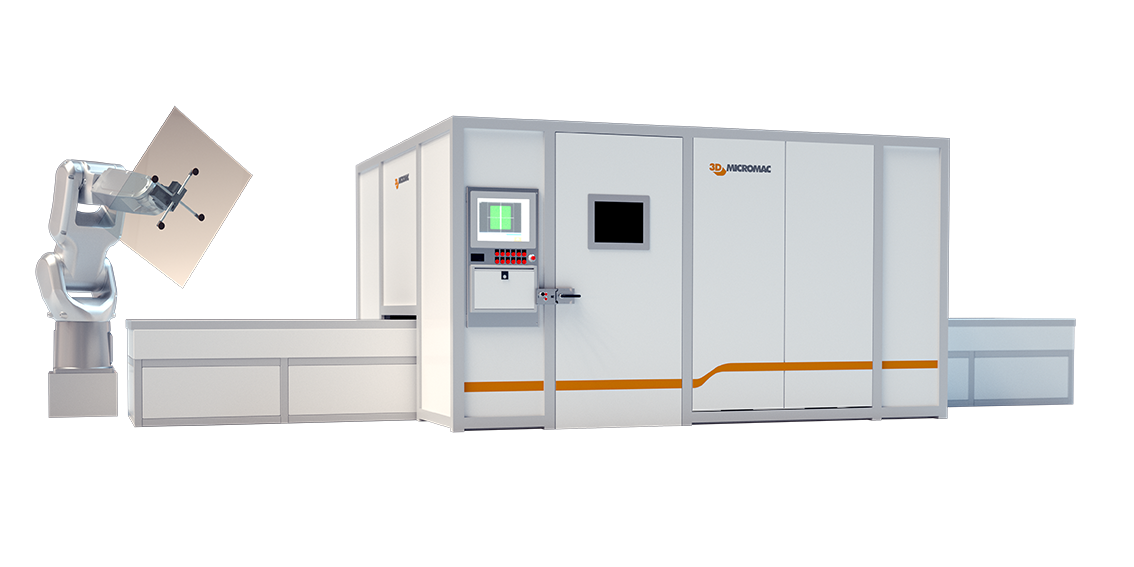

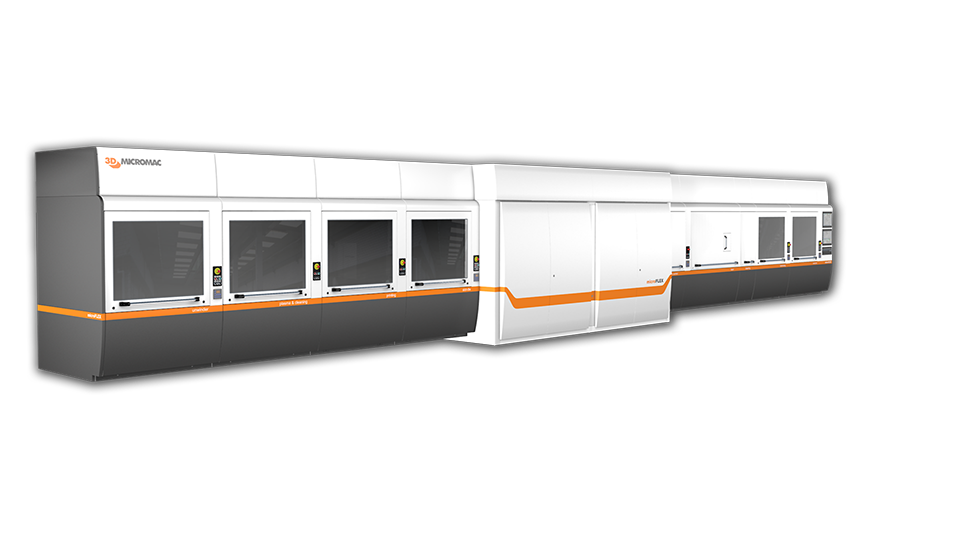

3D-Micromac AG is the industry leader in laser micromachining. We develop processes, machines and turnkey solutions at the highest technical and technological level. Our aim is to provide superb customer satisfaction even for the most complex projects.

3D-Micromac delivers powerful, user-friendly and leading edge processes with superior production efficiency. These proprietary technology innovations are now readily available on a worldwide scale.

Configurate your Laser System here!

News

Social Media

We are featured in the latest issue of Power Electronics World. Learn more about how 3D-Micromac's #microPRO #OCF #lasersystem provides selective #laserannealing for Ohmic Contact Formation 🤝 Thank you, #PowerElectronicsWorld! Read the full article here https://ow.ly/O9x950RgRjL

Today, Michael Grimm will speak about laser annealing as one possibility of surface modification at the #AKL24 in Aachen. Selective #laserannealing is used for ohmic contact formation #OCF on #SiCwafers and for programming #magneticsensors. #FrauenhoferILT

3D-Micromac

3D-Micromac 3D-Micromac AG

3D-Micromac AG