Laser Micro Drilling

Laser precision drilling enables generation of microholes with well-defined geometries

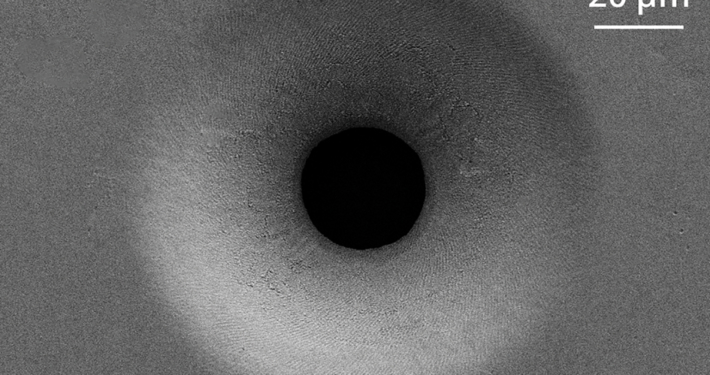

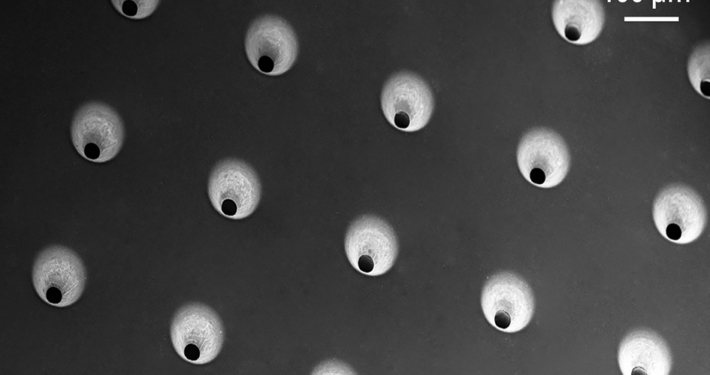

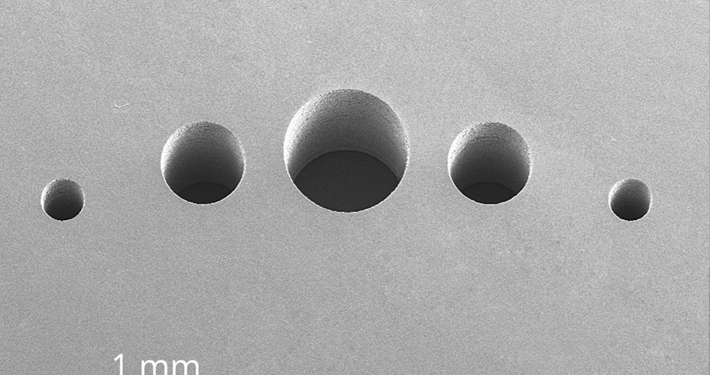

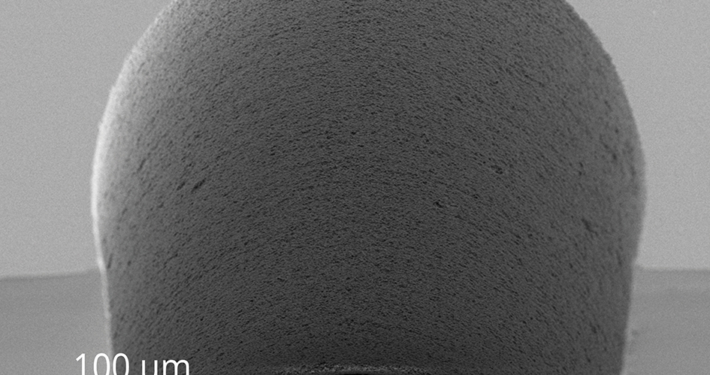

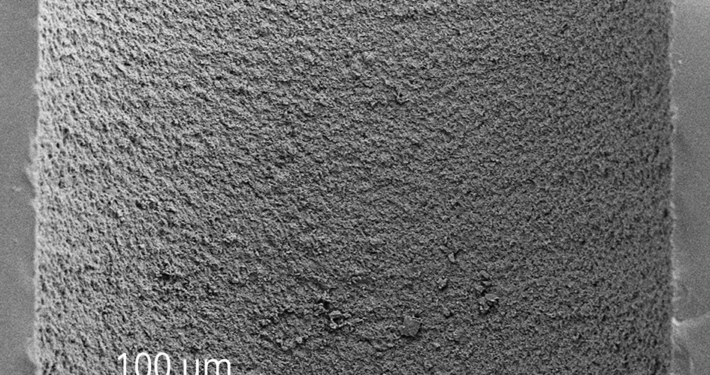

The drilling of microholes with well-defined geometries is gaining significance in a wide variety of industries. Laser drilling in turn is replacing conventional drilling processes to support many applications, ranging from the setting of micro-drillings in throughput flow filters and sieves, to via drillings in high-performance solar cells, and injection jets in the automotive industry. Laser techniques are gaining ground in the production of printer inkjets due to the laser’s touch-less processing, precise dosing of energy input, minimal heat transmission into the material, precision, and repeatability. Laser techniques also provide additional flexibility in defining the drilling geometries. For example, it is possible to generate microholes with a high aspect ratio (the relation between the drilling depth and the drilling diameter) or microholes with defined taper by varying the machining strategy during the laser process.

Depending on the application, a variety of lasers can be employed for micro-drilling. While excimer lasers and solid-state lasers working in the UV range are highly suitable for processing polymer substrates, solid state lasers in the visual or infrared range are used for machining of metals. However, selecting the right laser alone is not enough to ensure a successful outcome. Choosing the right drilling technique also plays a decisive role. Well-known among these techniques are percussion drilling and trepanning.

A particularly large development potential is attached to the usage of novel drilling heads or innovative machining strategies for generating of micro holes with precisely controllable taper in different materials.

Contact

Please contact our technical sales team for more information.

Frank Richter

Tel: +49 371 40043-222

sales@3d-micromac.com