TESCAN ORSAY Holding, a.s. and 3D-Micromac AG Collaborate to Increase the Efficiency of Failure Analysis Workflows

Synergy between both companies in the joint business and development activities creates a solid base for significant time and cost savings in the failure analysis (FA) workflows when compared to the current industry standard.

Chemnitz, Germany, December, 18 2020 – TESCAN, one of the leading companies in charged particle optics, 4D micro-CT and bespoke solutions, and 3D-Micromac AG, the industry leader in laser micromachining systems, collaborate to provide a more efficient workflow to diagnose a variety of materials and to root cause defects in functional materials and devices. Reducing the cost as well as time and skills demanding hours of labor to reach the region of interest (ROI), to just minutes.

Currently, samples of metals, semiconductors, ceramics, and compound materials are analyzed with focused ion beam (FIB) methods. TESCAN Plasma FIB-SEM is used throughout the semiconductor, automotive, and aerospace market segments as an industry-proven solution. These have, however, an increasing need for even larger volume material removal when FA is required on deeply buried ROIs or very large cross-sections.

“At TESCAN we are excited to vastly decrease the time-to-result of demanding failure analysis tasks, with the ability to analyze even larger volumes and create a much more productive workflow for industrial FA environments. We see a strong potential to create further synergies between TESCAN and 3D-Micromac portfolio as well as other FA tools in the FA labs to double-underline the meaning of solution,” said Jozef Vincenc Oboňa, Product Marketing Director at TESCAN. Typical sample preparation with Plasma FIB can take several hours and is mainly focused on FA tasks of sub-millimeter dimensions. “3D-Micromac’s microPREP PRO uses an ultra-short laser pulse ablation technique that allows the processing of much larger volume tasks in FA exceeding a cubic millimeter”, commented Tino Petsch, CEO at 3D-Micromac AG.

The current application solution is already reducing the FA time in most tested cases at least by 50%, in some applications even 95%. On average 75% of the overall time is saved by using TESCAN’s industry-proven Plasma FIB-SEMs together with 3D-Micromac’s flexible laser systems microPREP PRO. Further joint development will ensure that Plasma FIB-SEMs and microPREP PRO systems do not act as individual instruments but become an integral part of the FA lab ecosystem.

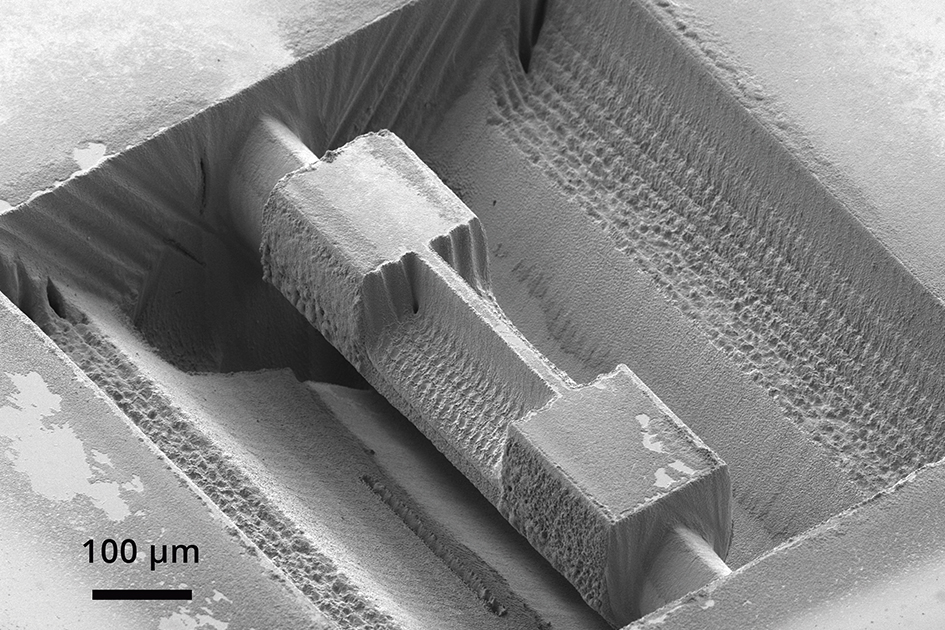

The microPREP PRO laser system for efficient sample preparation

The high ablation rate of the laser allows for a fast and easy preparation of samples for FIB processing

About TESCAN

TESCAN is one of the leading companies in charged particle optics, 4D micro-CT, and special solutions. The company was established in 1991 by R&D employees and service engineers of TESLA Company to continue in the traditional production of electron microscopes in Brno. TESCAN presented its first instrument PROXIMA in 1996. This and other model ranges booked TESCAN its place among renowned world producers. Long-term expansion and establishment of subsidiaries worldwide culminated in 2013 with the establishment of a holding with a French company ORSAY PHYSICS. This gave rise to TESCAN ORSAY HOLDING, which still keeps its headquarters, production, and R&D in Brno-Kohoutovice. Every TESCAN microscope is produced in Brno, even though roughly 95% of the production travels to customers worldwide. The biggest customers include universities, research centers, and industrial and production companies in various sectors. With nearly 30 years of experience in the scientific research area, over 600 employees, and 14 subsidiaries, TESCAN produces about 300 microscopes every year, which constitutes the annual turnover of approx. 100 million USD.

Further information: www.tescan.com

About 3D-Micromac

Founded in 2002, 3D-Micromac AG is the industry leader in laser micromachining, delivering powerful, user-friendly, and leading-edge processes with superior production efficiency. We develop processes, machines, and turnkey solutions at the highest technical and technological level. 3D-Micromac systems and services have been successfully implemented in various high-tech industries worldwide including photovoltaic, semiconductor, glass and display industries, micro diagnostics, and medical technology. For more information, visit the company’s website at https://3d-micromac.com/.

Contact:

Mandy Gebhardt

Teamleiter Marketing und Public Relations

3D-Micromac AG

Tel: +49 371 40043-922