Micromachining Excellence

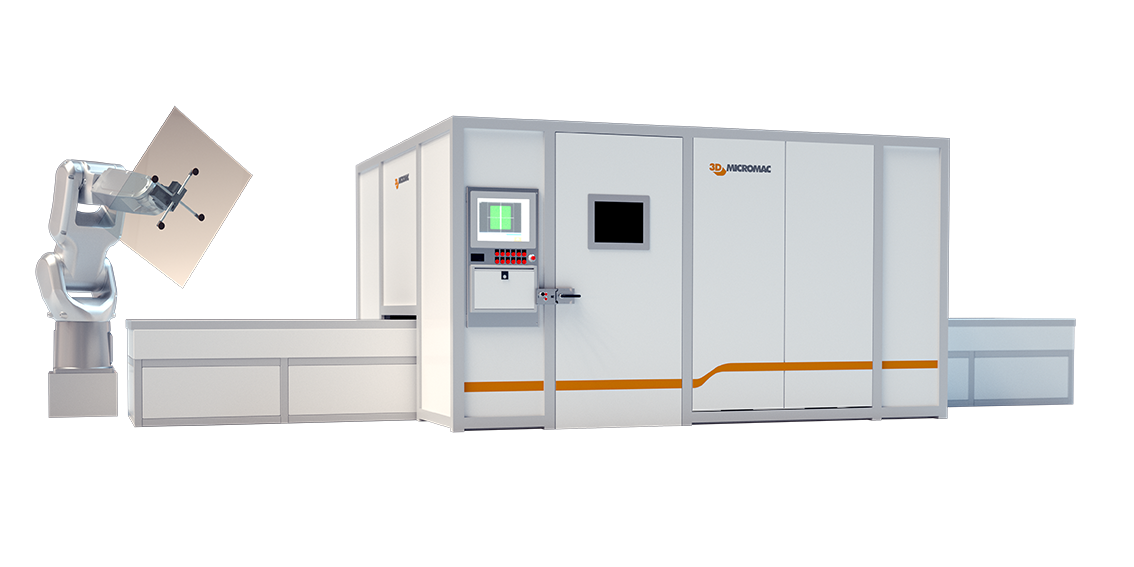

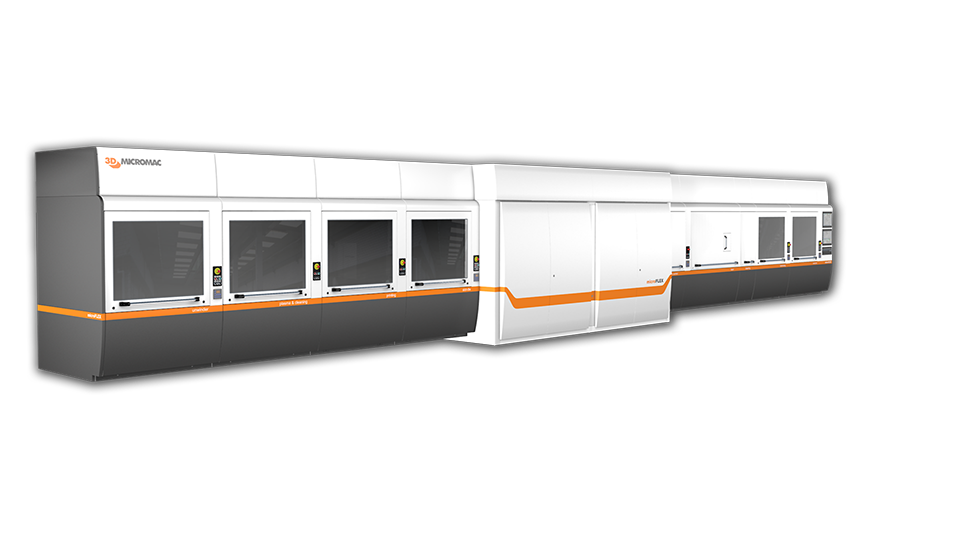

3D-Micromac AG is the industry leader in laser micromachining. We develop processes, machines and turnkey solutions at the highest technical and technological level. Our aim is to provide superb customer satisfaction even for the most complex projects.

3D-Micromac delivers powerful, user-friendly and leading edge processes with superior production efficiency. These proprietary technology innovations are now readily available on a worldwide scale.

Configurate your Laser System here!

News

Social Media

Es war uns eine Ehre: 30 interessierte Besucher - vom Studenten bis zum Senior-Ingenieur - waren der Einladung des #VDI gefolgt und informierten sich bei uns über #Lasertechnologie & deren vielfältige Einsatzmöglichkeiten. Danke an alle Teilnehmer!

After a successful day at #TouchTaiwan, Uwe Wagner (CEO) & Max Genz (Sales) were delighted with the great interest in our #lasersystem solutions for #microLED production. Take your chance and visit us at booth M310 Exhibition Center Hall 1,4F. Looking forward to meeting you.

3D-Micromac

3D-Micromac 3D-Micromac AG

3D-Micromac AG